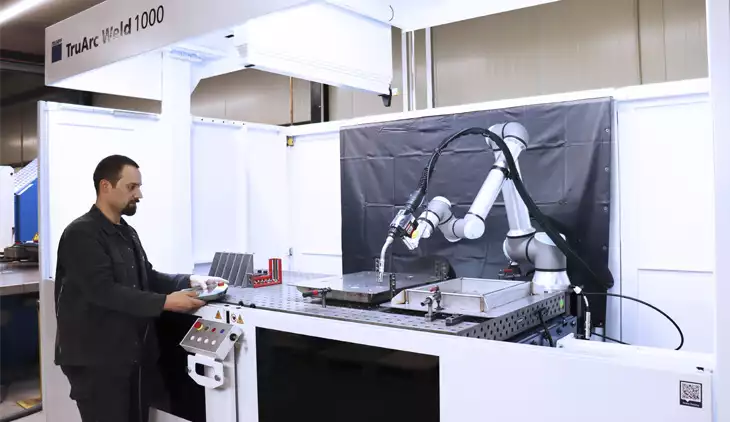

Productive welding with TruArc Weld 1000 robot

Welding cell with robot fast and flexible in use

Another welding robot complements the automated sheet metal processing at BVS Blechtechnik. In the TruArc Weld 1000 welding cell from Trumpf, the welding robot is very easy to program and can be used profitably even for small quantities. Increased welding requirements for new projects and recurring parts make the investment in the compact machine worthwhile.

The TruArc Weld 1000 is flexibly equipped and can be used in 1- or 2-station operation. “In alternating operation, we can set up the parts on one side while the robot welds with consistent quality on the other side,” explains Harald Steiner, Managing Director at BVS Blechtechnik. The extremely simple programming is a real highlight: the skilled worker enters the welding start and end point directly via buttons on the welding torch. Then the robot arm is moved manually from waypoint to waypoint and the welding parameters and templates for welding programs are already stored. Stored series parts can also be operated by employees without welding skills, which provides planning security in times of a shortage of skilled workers. The system runs in 2-station mode for parts up to 600 mm in size or the side panels and ceiling can be opened easily and large parts up to 2000 mm in length processed in 1-station mode.

In contrast to the laser welding robot that has been in use at BVS for 12 years, the TruArc Weld 1000 uses a special welding power source from Fronius for automated arc welding applications. Gap-bridging welding is easy to implement and ensures precise welding processes with the best results and quality. No welding spatter or beads are visible on the seams, which means less rework than with manual welding. The welding cell was set up in the production hall within a few hours and could be put into operation by the specialist welders without any training – only video tutorials were required for programming and operation.

The fast and reliable welding with the TruArc Weld 1000 has clearly convinced the management at BVS, and further systems have already been ordered from Trumpf for both BVS Blechtechnik in Böblingen and BVS Systemtechnik in Schwerin.