Device manufacturing

Component assembly: huge variety of sheet metal housings and electronic devices

The sheet metal and bent parts manufactured in the upstream production, together with electronic components, become a single unit in the component assembly at BVS Blechtechnik. Our experienced fitters assemble the previously lasered, punched, bent and welded individual parts as a housing or complete end product. On the 1,800 m² assembly area, products are created for almost every field of application: whether for the electrical engineering industry, medical technology, measurement technology, for flight seats or information systems – we manufacture your individual system in almost unlimited variety.

Component assembly: Project support & assembly

All-round project support

Our project support for terminal installation is available for extensive tasks. From the drawing to the installation of the electronics provided, we work closely with the customer to coordinate the ideal complete solution. For example, we accompanied the production of outdoor information pillars for a retail chain. The project started off with the development of a prototype and ended with the delivery of the series to the individual retail locations within two years. After a test phase in 30 stores, the BVS team optimized the displays for all weather conditions and produced the digital terminals for 1600 stores at intervals on a large project area.

Our project support for terminal installation is available for extensive tasks. From the drawing to the installation of the electronics provided, we work closely with the customer to coordinate the ideal complete solution. For example, we accompanied the production of outdoor information pillars for a retail chain. The project started off with the development of a prototype and ended with the delivery of the series to the individual retail locations within two years. After a test phase in 30 stores, the BVS team optimized the displays for all weather conditions and produced the digital terminals for 1600 stores at intervals on a large project area.

Assembly in workshop manner

Depending on the complexity of the end product, the fitters at BVS adapt their workstations to find the ideal process sequence for the respective assembly. The eleven individual workstations are equipped with height-adjustable assembly tables and computer systems. Via the digital archive, the fitters call up the 3D models and find assembly instructions documented in pictures for the optimum assembly of the enclosures. They accomplish this either by conventional assembly on a workbench or in a one-piece flow via two, three or four assembly islands.

This system is used by BVS, for example, for an aircraft seat console consisting of over 1000 individual parts, including stamped aluminium parts, clip nuts, rivets, edge protectors or cable holders, which are manufactured over several assembly steps. The complete assembly is integrated between the flight seats at the end customer and is used to store consumer electronics, table and life jackets. Assembly islands allow flexible processing of the high number of variants of the assemblies. Even small quantities can be efficiently inserted in the workshop production at BVS.

Component assembly: ESD assembly

Safe ESD mounting

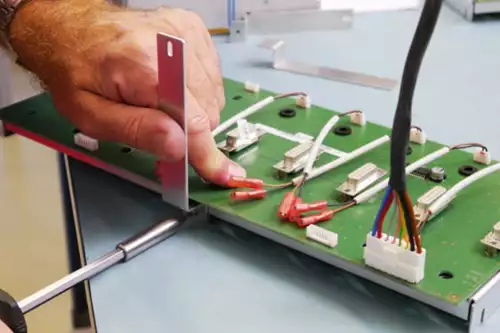

A specially secured area is available for the assembly of electronic components. To protect the sensitive electronic control elements against electrostatic discharges and non-visible damage, the tables are dissipative and the floors are protected with a coating. A long-standing customer from the medical technology industry trusts in BVS’ expertise in ESD assembly. For him we assemble, for example, blood analysis devices made of powder-coated housings, 3-part doors including electronic parts and drive motors as well as test tube holders. In cooperation with the customer, the sample product with its special requirements is discussed at BVS or at the customer’s premises and assembled together. Before the devices are shipped or stored, each device is tested and we record this test in detail – thus we reliably deliver the desired quality.

Experienced technical personnel

The experienced team of industrial mechanics, electronic technicians and a master craftsman stands for the professional assembly of the modules and ESD components at BVS Blechtechnik. With their specialist training, internal and external training courses and the intensive know-how gained from practical experience, they assemble a wide range of housings and end devices for a wide range of applications. The enormous product variety of listed component orders reflects the flexible performance of sheet metal processing and assembly at BVS Blechtechnik. In order to manage this abundance of products, BVS continuously adapts its assembly processes. The optimisation of the fixtures, intermediate storage and material flow and the continuous training of our personnel ensure an economical and high-quality result for the assembly of components at BVS Blechtechnik. Would you like advice on the assembly of your module or a complete system? Our technical consultants will be pleased to assist you:

BVS Blechtechnik GmbH

Hanns-Klemm-Str. 15

D-71034 Böblingen

Fon: +49 (0) 7031 / 7164 – 0

E-Mail: info@bvs-gruppe.de