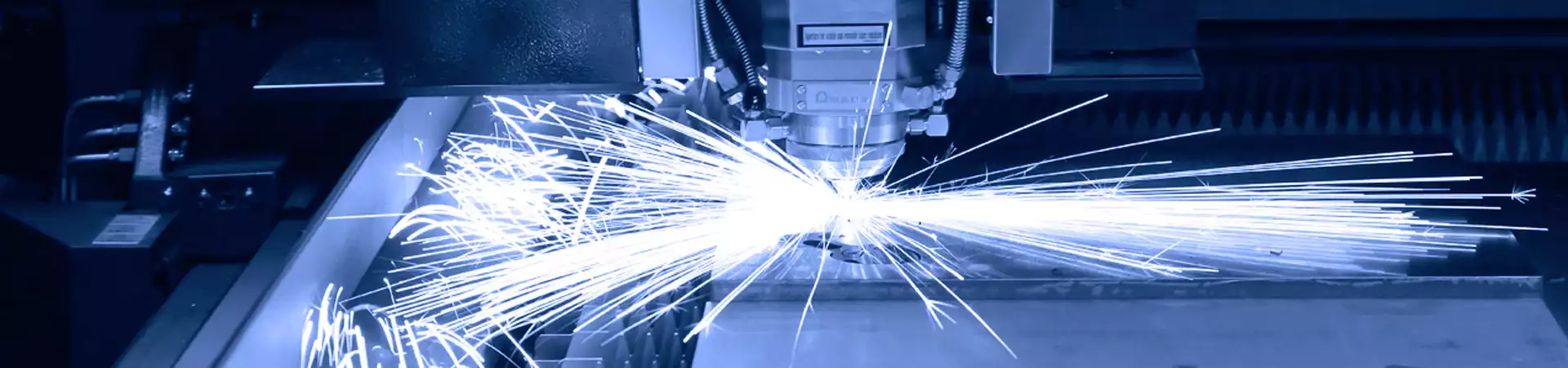

Punching/ Laser cutting

Punching/laser cutting is our passion. We are your specialist for precise sheet metal cutting and laser processing. We process a wide range of metals, from aluminium to steel, stainless steel and copper, according to your wishes and dimensions. Our extensive range of services in the field of punching and laser cutting covers a wide range of areas:

Punching/laser cutting: Which techniques do we offer?

We cut your sheet metal using the latest laser technology. The punching area offers the option of forming sheet metal parts or inserting threads – all on one machine. The CNC machines are complemented by the latest automation options to further increase productivity.

What machines are available for punching/laser cutting?

We have six machines for the metalworking processes of punching and laser cutting, each equipped with a fully automatic connection to our material storage system. In addition, handling components are installed for loading/unloading raw materials and finished parts.

On a punching machine from Trumpf, we process stainless steel blanks up to 6 mm and aluminium blanks up to 8 mm very quickly at up to 1,600 strokes/minute and with a high part quality. With a selection of over 3,000 tools, the machine performs the required punching, forming or countersinking operations and cuts out threads. The punching machines are particularly suitable for small and medium-sized sheet metal series with complex contours.

What possibilities do our three fully automated punch laser systems offer?

The three fully automatic punch laser systems, two Trumpf TruMatic 6000Fibre and Amada EML-Z, combine the punching and laser cutting processes. They can be used flexibly for complicated parts with special contours and quickly perform a wide variety of forming operations. A maximum of 6 mm steel, 4 mm stainless steel or 6 mm aluminum plates are processed with a virtually scratch-free result.

The extensive tool stores for tool changes parallel to production time enable an automated production cycle.

Sheet formats with dimensions of up to 2500 x 1500 mm can be processed. The machine control is equipped with integrated order and tool management.

The fiber laser systems Amada Ventis 3015 AJ and Amada FOL 3015 prove to be true all-rounders, because they process stainless steel, steel and aluminum, copper as well as brass. With a significant reduction in energy consumption, these systems offer a solution for every task in the cutting process. Thanks to LBC technology, the Amada Ventis offers extremely high power intensity in the laser beam for a consistently high-quality cut.