25 years as a certified company

Tested quality for customized sheet metal products

BVS Blechtechnik implemented quality management for the first time back in 1997 and has therefore met the quality requirements of the ISO 9002 and ISO 9001:2015 standards for 25 years. This means 25 years of practiced quality awareness and continuous further development as well as constant adaptation of procedures and processes in the company, resulting in the production of high-quality products made of thin sheet metal. “At BVS, systematic performance improvement is an important building block in our success story, which is internalized and lived by everyone from management to trainees,” explains Harald Steiner, Managing Director at BVS Blechtechnik.

It was only at the end of May that TÜV Rheinland checked all points of the ISO 9001:2015 standard during an audit lasting several days. The auditor examined the tasks of the management, various areas such as purchasing, customer order processing, production, accounting and processes in the HR and marketing departments. With the certification, which is valid for a further three years, the experts confirm the quality of the expertise in all production and administrative processes.

Goals and continuous improvement

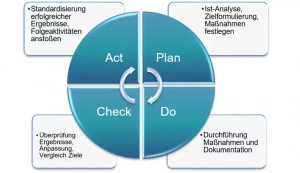

“Quality is not a matter of chance; it is always the result of hard thinking,” says a quote from British social philosopher John Ruskin. This is reflected in the certified management system at BVS, according to which the regulated processes and structures are implemented in a cycle of continuous improvement. This is preceded by aspects such as analyzing the requirements of all interested parties, opportunity/risk assessments and defining corporate strategies and policies. Ultimately, our goals, such as high customer satisfaction, reliable delivery times, low complaints, error prevention, retention of know-how or low internal scrap rates, are clear parameters that are pursued at BVS. All of this is organized according to the plan-do-check-act approach.

What sounds theoretical at first, we illustrate with concrete examples in the company. These exemplary improvements were implemented in various areas and provide an insight into the countless measures implemented to optimize processes, employee training and machinery:

- In order to avoid subsequent errors in production during welding or riveting, instructions in the system with easy-to-understand images provide clear instructions for ongoing jobs as soon as a work process is started

- Internal logistics were reorganized so that, among other things, logisticians carry out the internal transport from one production process to the next. Structured and expanded storage locations in the respective departments enable a more efficient process

- Recruitment of a full-time employee for internal training and development. The employee takes on the close supervision of the trainees and provides regular training for skilled workers

- Energy management/energy savings: Analysis of major sources of energy consumption in the plant, including replacement of lighting and machinery

From standardization to sustainability

Sustainability in particular is just as important to us as economic processes: whether in the efficient use of materials and energy, ecological investment decisions for new systems or the avoidance of environmentally harmful substances. We define our specific environmental goals on an ongoing basis in our environmental management strategy and are constantly expanding our environmental protection measures.

Certification applicable for broad fields

The quality management of the 9001:2015 standard covers all quality-relevant activities and procedures at BVS and is therefore universally valid for all areas of application of sheet metal products, assemblies and end devices. BVS Blechtechnik uses its cross-industry expertise and experience to manufacture high-quality products to meet the requirements of the electrical engineering industry, information technology, medical technology, measurement technology, telecommunications and aviation. Because for us, quality is not a bonus, but a matter of course.