Assembly at BVS – complete. tested. ready for use.

From precise sheet metal processing to tested final assembly: at BVS Blechtechnik, you receive individually assembled components – manufactured to fit perfectly, electronically equipped, ESD-compliant and ready for immediate use. Thanks to flexible workplace concepts, digital assembly aids and in-depth expertise, we can master complex requirements – for example in medical technology, aviation or information technology.

Your advantages at a glance:

Modular and economical: even small series and individual items can be efficiently produced

Modular and economical: even small series and individual items can be efficiently produced- Complete service: From housing production to final assembly, everything from a single source

- ESD-safe assembly: protection of sensitive electronics by trained specialists

- Digital processes: 3D models & visual instructions for the highest quality

- Project experience: Support from prototype to series production – across all industries

What does component assembly mean at BVS?

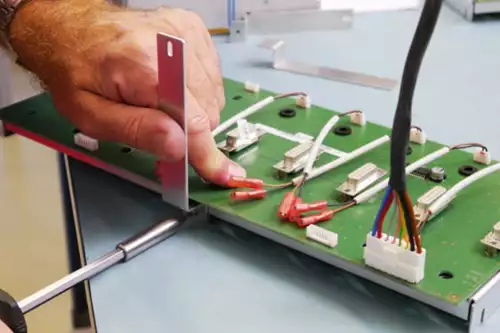

At BVS Blechtechnik, component assembly is much more than simply putting individual parts together. Complete system solutions are created in a modern 1,800 m² assembly area – from simple housings to complex end devices with integrated electronics.

The sheet metal and bent parts manufactured in the upstream production, together with electronic components, become a single unit in the component assembly at BVS Blechtechnik. Our experienced fitters assemble the previously lasered, punched, bent and welded individual parts as a housing or complete end product. Products for almost every area of application are manufactured on the 1,800 m² assembly area: whether for the electrical engineering industry, medical technology, measurement technology, aircraft seats or information systems – we manufacture your individual system in almost limitless variety.

Component assembly: huge variety of sheet metal housings and electronic devices

Whether it’s a single item, prototype or series product – thanks to our flexible assembly processes and close coordination with our customers, we manufacture exactly what is needed: precisely tailored, economical and reliably tested.

Convincing diversity – for medical technology, aviation and more

Our assemblies are used wherever precision, flexibility and process reliability are required:

- Medical technology: ESD-compliant assembly of blood analysis devices, including drives, pneumatic doors, or microwave laboratory systems

- Luftfahrt: Flugsitz-Konsole mit über 300 Einzelteilen, darunter gestanzte Aluminiumteile, Kantenschutz, Elektronik und vieles mehr

- Laboratory technology: Mercury analyser – from sketch to series production in just four months

- Retail: Digital information kiosks for 1,900 locations – including prototyping, test run and series production

Whether high-end enclosures or complex system solutions: our team assembles your components with precision and technical expertise.

Flexible manufacturing – even for small batch sizes

Thanks to our workshop concept with flexibly adaptable workstations, even small batch sizes can be produced economically. Our fitters work at digitally supported individual workstations with 3D models and illustrated assembly instructions. This means that even individual items or changing assemblies can be manufactured efficiently and reproducibly.

One-piece flow, assembly islands or individual workstations – we set up the optimal environment depending on the complexity of the product. This saves time, prevents errors and increases flexibility for custom-made products.

Sensitive electronics? No problem with our ESD assembly

A separate ESD area is available for the assembly of sensitive electronics:

- Conductive tables & coated floors

- Regular checks & documented testing processes

- Trained employees for ESD-compliant work

- Transparent logging of all assembly steps for maximum traceability

This is how we ensure that sensitive components – e.g. control electronics in medical technology – are assembled in a reliable, safe and durable manner.

Digitally supported – for greater efficiency and quality

Our workplaces are fully digitised: instead of paper drawings, we use 3D models and visual instructions that can be accessed directly via our IT systems. This not only makes training and assembly easier, but also improves reproducibility and quality.

- Avoid errors with intuitive, image-based processes

- Faster knowledge transfer within the team

- Better understanding of complex assemblies through digital visualisation

The result: less waste, shorter turnaround times, higher customer satisfaction.

Expertise meets practice: our team makes the difference

At BVS, the focus is on modern manufacturing, qualified specialists and comprehensive quality testing – for customers who value economical processes and the highest quality in component manufacturing.

Our experienced team consists of industrial mechanics, electronics engineers and specialists with many years of practical experience. Regular internal and external training ensures that our employees have the necessary expertise and remain up to date – this knowledge is particularly crucial when it comes to complex or new assemblies.

- Close teamwork for high flexibility

- Proven processes even with changing products

- Maximum reliability, supported by regular maintenance of the machinery

- Quality from the very first component: we pay attention to certified quality right from the parts procurement stage.

The enormous product variety of listed component orders reflects the flexible performance of sheet metal processing and assembly at BVS Blechtechnik. In order to manage this abundance of products, BVS continuously adapts its assembly processes. The optimisation of equipment, intermediate storage and material flow, as well as the continuous training of our staff, ensures economical and high-quality results for component assembly at BVS Blechtechnik.

Get advice now – for your assembly made in Germany

Whether it’s a single item, small series or complex electronic systems: we assemble your components economically, precisely and reliably – from the housing to the final inspection.

📞 +49 (0) 7031 / 7164 – 0

✉️ info@bvs-gruppe.de

📍 BVS Blechtechnik GmbH, Hanns-Klemm-Str. 15, 71034 Böblingen

Our individual consultation service helps you find the right assembly solution for your project – whether in mechanical engineering, medical technology or other demanding industries.

Frequently asked questions about component assembly

What does assembly mean at BVS Blechtechnik?

Assembly at BVS Blechtechnik encompasses the entire concept on a modern assembly area covering 1,800 m². Our experienced fitters assemble the sheet metal and bent parts manufactured in-house together with electronic components to form a single unit – and in doing so, they achieve much more than simply putting individual parts together. This results in complete housings or end devices – from simple sheet metal housings to complex devices with integrated electronics. We manufacture individual systems in an almost unlimited variety for a wide range of industries, including medical technology, aviation, measurement technology, electrical engineering and digital information systems.

Thanks to decades of experience in manufacturing technology, BVS Blechtechnik implements tailor-made solutions for companies that rely on high-quality component assembly, forming processes and reliable quality control.

What are the advantages of single-source component assembly?

At BVS Blechtechnik, you receive all services from a single source, which offers you considerable advantages. We cover the entire process, from precise sheet metal processing to tested final assembly. Your benefits at a glance:

- Modular and economical: even small series and individual items can be produced efficiently and cost-effectively.

- Complete service: From housing production to final assembly – you receive the entire assembly process seamlessly and without any interface losses.

- ESD-safe assembly: Trained specialists work in ESD-protected areas to protect sensitive electronic components from electrostatic discharge.

- Digital processes: 3D models and illustrated assembly instructions support our fitters and ensure consistently high quality in every installation.

- Project experience: We accompany your product from prototype to series production – across all industries and with comprehensive expertise, so that your assembly is quickly ready for use.

Does BVS Blechtechnik also assemble prototypes and small series?

Yes. Thanks to flexible assembly processes, BVS Blechtechnik can also assemble individual prototypes and small series economically. We use modular, adaptable workstations – depending on the complexity of the product, we use individual workstations, one-piece flow lines or assembly islands to ensure the optimal workflow. Supported by digital 3D models and visual instructions, even individual items can be manufactured efficiently and reproducibly. This flexibility saves time, minimises errors and also enables custom-made products and sensitive electronic assemblies of the highest quality – precisely assembled and reliably tested.