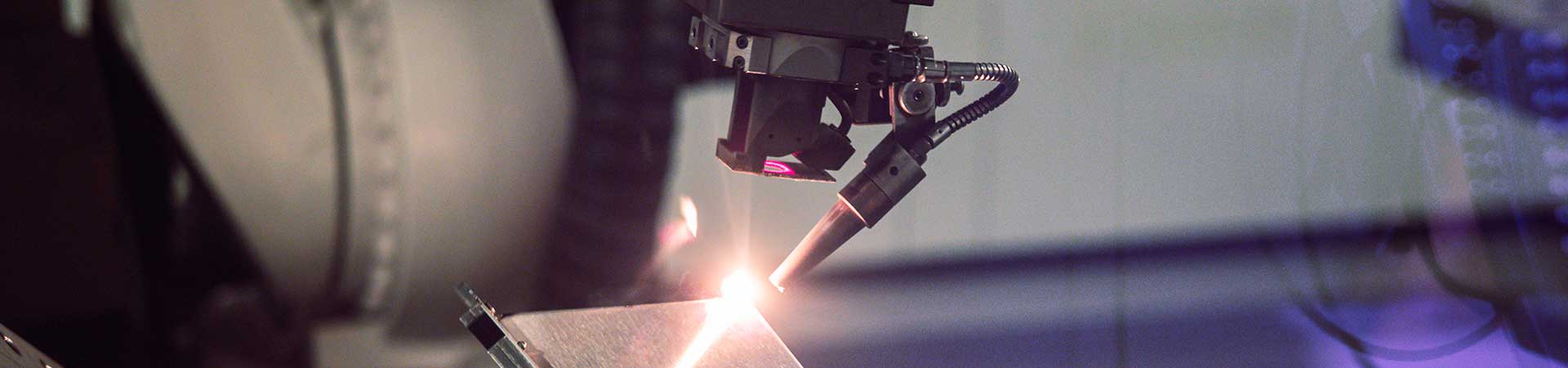

Laser welding – Efficient solutions for modern manufacturing processes

Laser welding is a state-of-the-art welding process based on the precise interaction of laser radiation with the material. This results in precise, narrow weld seams with minimal heat input. In Böblingen, we use this technology to produce delicate, high-precision welds economically and reproducibly – from prototypes to large series.

The laser works contact-free at high speed and ensures that even components with tight tolerances and complex geometries are welded reliably.

BVS Blechtechnik is your reliable partner for series production – efficient, precise and individually tailored to your requirements.

Your advantages at a glance:

Efficient production from prototypes to large series

With state-of-the-art fibre laser systems, we manufacture economically and reproducibly – from small batch sizes of approx. 10 pieces to large series. Ideal for sample parts, series start-ups or recurring orders.

Highest precision thanks to modern laser technology and process control

Our Trumpf TruLaser Weld 5000 and AMADA FLW-Le with ENSIS technology enable extremely narrow, clean weld seams – even with complex geometries and tight tolerances. Digital process monitoring and documented quality checks ensure consistently high results.

Optimised processes – from CAD data set to finished component

We use your CAD data to generate the complete manufacturing process. Material flow, laser parameters and quality control are prepared automatically – for short throughput times and maximum process reliability.

Flexibility in materials, component sizes and gap dimensions

Whether stainless steel, aluminium or non-ferrous metal – we weld a wide variety of materials precisely and with minimal distortion. From small 70×70 mm components to workpieces up to 2 m long, we can cover everything. And thanks to ENSIS technology, larger gap bridging is also possible.

Technological expertise and personalised advice

Benefit from our experience in laser welding technology: we recommend the optimal process tailored to your component geometry, material selection and economic goals – for results that are technically and economically convincing.

Fundamentals of laser welding

Laser welding is an established industrial process for joining components with maximum precision and minimal energy input. Through the targeted use of laser power, heat is only applied where it is needed – for low-distortion, economical results.

In laser welding, a highly focused laser beam hits the workpiece, creating a precisely defined melting zone and opening a so-called keyhole – a fine vapour channel that completely absorbs the laser energy. The heat is distributed specifically in the material, the melt cools quickly and forms a precise, clean weld seam. The exact adjustment of laser power, welding speed and additional parameters allows both the seam geometry and the welding quality to be optimally controlled. The process is suitable for numerous metals – from aluminium to stainless steel to copper – and enables reproducible results even with complex geometries.

Laser beam and welding process

The focused laser beam is the central tool in laser welding. Thanks to its high energy density, it melts the metal with pinpoint accuracy, enabling particularly narrow, clean seams – ideal for components with complex geometries and tight tolerances. At BVS in Böblingen, two modern fibre laser systems are used for this purpose: the Trumpf TruLaser Weld 5000 with a shuttle table for larger quantities and setup during production time, and the AMADA FLW-Le with ENSIS technology, which enables particularly large gap bridging. Both systems also process non-ferrous metals and, thanks to precise process control, optimum laser power, welding speed and shielding gas supply, ensure consistently high seam quality – reproducible and economical.

Added value for customers through laser welding at BVS

Laser welding in Böblingen offers customers clear advantages in terms of quality, repeatability and efficiency. Thanks to precise process control and low heat input, clean, durable welds with minimal distortion are produced. This precision pays off, especially for components with high tightness requirements – as in the case of pressure testing: components reliably meet the required specifications, which not only prevents complaints but also often leads to follow-up orders.

The technology is extremely flexible: in Böblingen, both the smallest components measuring just 70×70 mm and large workpieces such as 2 m long door handles can be machined economically. Different geometries and materials – from stainless steel to non-ferrous metals – are processed with the same precision.

Water rails for test systems in semiconductor manufacturing are a clear example of the capabilities of this process. These components must be completely leak-proof and withstand subsequent pressure testing. The use of laser welding not only significantly improved the quality of the parts, but also optimised the entire process. BVS carried out all the work steps on site in Böblingen – from production to final testing – and delivered a ready-to-install, tested end product to the customer.

Frequently asked questions (FAQ) about laser welding

What are the advantages of laser welding?

This results in extremely precise, clean weld seams with minimal heat input. Components remain distortion-free and meet even tight tolerances – ideal for complex geometries.

What materials and component sizes can be processed?

We reliably weld stainless steel, aluminium and selected non-ferrous metals. We can handle components ranging from the smallest parts (70×70 mm) to workpieces up to 2 m in length.

Is laser welding also suitable for series production?

Yes. From small batch sizes of around 10 pieces to large series, we manufacture economically, precisely and reproducibly – ideal for prototypes, series launches or recurring orders.