Efficient sheet metal punching: an overview of techniques and applications

Precise sheet metal punching – economical, fast and reliable

Whether functional perforations, multiple holes or complex geometries: BVS Blechtechnik supplies stamped parts of consistently high quality – from individual parts to series production, including further processing and complex assemblies.

- Efficient series production thanks to short cycle times and automated processes

- High precision and dimensional accuracy even with complex contours and functional elements

- Combination with laser cutting and forming – for cost-effective complete solutions from a single source

BVS Blechtechnik is your professional partner for punching sheet metal parts – efficient, dimensionally accurate and ideal for series or recurring contours.

Sheet metal punching – efficient, precise and versatile

Punching is a key process in sheet metal working – wherever precise contours, high quantities and repeatable results are required. Special tools are used to punch, pierce or shape sheet metal to produce functional or ready-to-assemble parts.

At BVS Blechtechnik, punching is not just a classic manufacturing step – it is a highly efficient process that has been perfected through automated machines and tailor-made tool technology. Whether complex loudspeaker grilles with multiple perforations, gills, threaded passages or other functional elements: the benefit lies less in the number of units produced than in the cost-effectiveness of recurring geometries and special contours.

Advantages of punching at BVS:

- High throughput thanks to short cycle times and modern machine technology

- Cost-effective production of complex structures (e.g. slotted bridges or special contours)

- Consistent results with minimal material loss

- Optimised for series production, assemblies and system components

Depending on the component geometry, punching is used as a stand-alone process or in combination with other processes such as laser cutting or bending – for a result that is technically, economically and functionally impressive.

Stamped parts – precisely manufactured, versatile in application

Stamped parts are metal components that are produced by controlled punching or breaking through sheet metal – often in large quantities and with high repeat accuracy. They are used in a wide variety of industries, such as electrical engineering, medical technology, sensor technology and automotive engineering.

At BVS Blechtechnik, the quality of a stamped part begins with the selection of materials: sheets with thicknesses ranging from 0.5 to 3 mm are stamped, regardless of the material. Whether stainless steel, aluminium, steel or coated sheets – the decisive factors are the combination of the right tools, experience in process management and a clear understanding of the requirements for the component.

Even small differences make a big difference here:

✔ Minimal burr formation

✔ Warpage control

✔ Material-friendly punching

✔ Precise hole geometries

✔ Clean edges

Our tool expertise – precisely tailored to every contour

When it comes to punching in Germany, BVS relies on customised standard tools – and, if necessary, switches to a laser punching combination machine in order to economically produce special contours or complex geometries. The tools are precisely tailored to the respective requirements in close cooperation with customers.

For larger series or assemblies with defined repeat patterns, our locations in China offer progressive moulds and other special solutions – organised and supported by our German engineering team.

Your benefits at a glance:

- Stamped parts made from all common materials – reliable and dimensionally accurate

- Ideal for series production with defined geometries and functional elements

- High-quality tool solutions – efficient, flexible, application-specific

- Clean results through targeted burr prevention and material-appropriate processing

Punching machines & punching techniques – versatile, automated, efficient

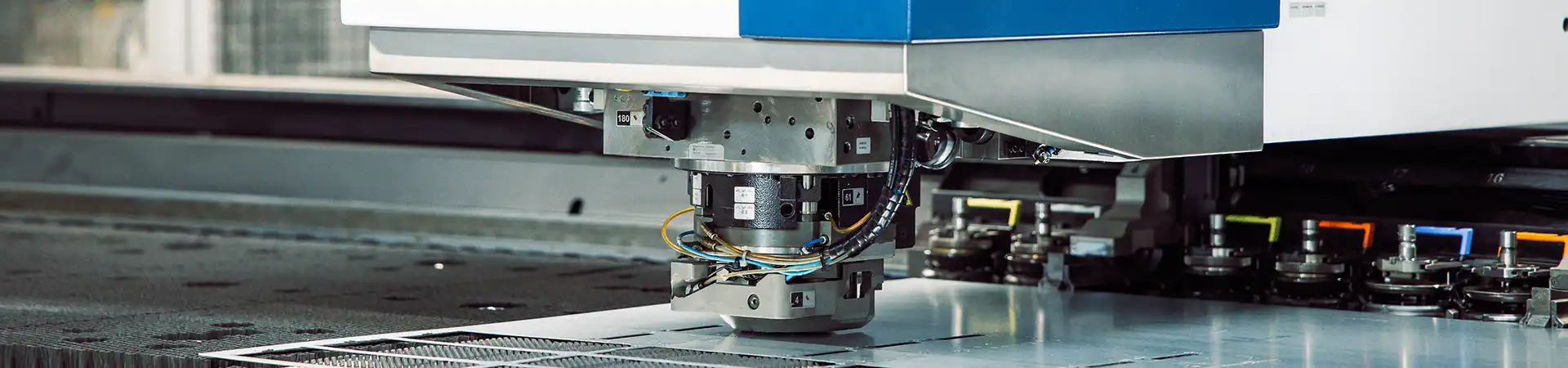

Punching machines are designed to process sheet metal quickly, precisely and economically. With modern systems, various punching techniques such as hole punching, breakthroughs, recesses or gills can be implemented with precision – even with complex geometries or tight tolerances.

BVS Blechtechnik uses high-performance machines that can be flexibly equipped with different tools and dies. This allows the shape, size and function of the stamped parts to be precisely adapted to the respective application – with high process reliability and minimal waste.

Stanzen im System – clever kombiniert, besser kalkulierbar

The major advantage of BVS lies in the intelligent combination of the punching process with other work steps – directly in a single operation. Depending on the component and contour, the following can be achieved, for example:

- Forming, countersinking or thread cutting

- or combined solutions involving punching and laser cutting

This saves set-up times, reduces sources of error and ensures precise coordination of all process steps.

Downstream production steps such as bending, assembly and surface finishing are also integrated at BVS – for a continuous workflow from a single source.

Benefits for your production:

- Zeit- und kosteneffizient durch Kombination mehrerer Arbeitsschritte

- Less handling, shorter throughput times, less material loss

- High flexibility with changing batch sizes and contours

- Ideal for economical series production and demanding components

Punching and laser technology at BVS – flexible, precise, economical

Complex sheet metal parts require flexible technologies – this is precisely where the punching and laser systems at BVS Blechtechnik come into play. Three fully automated combination machines – two Trumpf TruMatic 6000 Fiber and one Amada EML-Z – combine the advantages of classic punching with the precision and design freedom of laser cutting. These combine the advantages of classic punching with the precision and design freedom of laser cutting – in a single, continuous production step.

The result: high-precision, economically manufactured components with complex contours, functional openings and optimum edge quality – ideal for series components in the electrical, medical and mechanical engineering industries.

Typical components from BVS production:

- Support plates and housing parts with combined functional openings

- Series parts with punched and laser-cut geometries

- Assemblies for electronics, medical technology or industrial plants

Advantages and limitations of punching – and how BVS utilises it

Punching is one of the most efficient processes in sheet metal working – especially for series with recurring geometries. It enables:

✔ High cycle rates and short production times

✔ Low unit costs thanks to automated processes

✔ High precision and repeatability

✔ Option to combine with forming, threading or surface treatment

However, not every geometry can be punched. Very fine contours, extreme material thicknesses or variable individual pieces are often better achieved by laser cutting or a combination of both processes. BVS therefore analyses each project individually – and recommends the best solution in terms of both technology and economy.

Consistent quality – even with large quantities

When it comes to large series, it is not only speed that counts, but also reliability. That is why BVS uses a clearly defined quality system to ensure that every part is dimensionally accurate, functional and visually appealing:

- Digital order control and seamless process documentation

- Tool maintenance and regular inspection cycles

- Integrated visual and dimensional inspections during production

- Many years of experience in dealing with critical tolerances

The result: reliable quality from the first to the last component – with demonstrable advantages in terms of delivery time, costs and further processing.

Metalworking and sheet metal processing at BVS – versatile and tailored to requirements

Metalworking at BVS encompasses a wide range of precision manufacturing processes, including punching, laser cutting, forming and welding. Each process is precisely tailored to the material, component geometry and subsequent application. Whether aluminium, stainless steel or coated sheet metal – our expertise ensures that every part is dimensionally accurate, functional and reliable. This results in solutions for demanding industries such as the automotive, electronics and mechanical engineering sectors – reliable and efficient.

The future of punching – digital, precise and sustainable

Punching technology is constantly evolving – primarily through digitally controlled processes, new tool technologies and hybrid machine concepts such as the punch-laser combination. The trend is clearly moving towards higher precision, automated processes and resource-saving production. For BVS, this means continuous investment in modern technologies and a strong focus on integrated, sustainable process chains. This will ensure that punching remains a key process for the economical production of complex sheet metal parts in the future.

FAQs about sheet metal punching at BVS Blechtechnik

For which applications is the punching process particularly suitable?

The punching process is ideal when precise holes, openings or special deformations need to be made in metal parts in a cost-effective manner. It is mainly used in series production with recurring geometries – for example, in housings, carrier plates or sheet metal parts for machine and equipment construction.

Which punching tools are used at BVS – and how flexible is the operation?

BVS uses high-quality standard punching tools that are individually adapted to the requirements of the component. For complex or non-standard geometries, several laser punching combination machines are also available, offering maximum flexibility in terms of shape, material and batch size.

How does BVS ensure that no undesirable deformations occur during punching?

Precise tool guidance, material-specific cutting parameters and continuous quality controls reduce deformation to a minimum. Each metal is processed with the appropriate punching tool – this ensures that dimensional stability is maintained even with thin sheets and filigree holes. Should warping and process-related deformation occur nonetheless, BVS is able to compensate for this through straightening operations.